k-Core® Radiator Panels — Ensuring Performance in Space

For critical thermal management needs, including heat dissipation requirements of ≥ 40°C reduction, communications satellite and spacecraft engineers turn to k-Core passive thermal radiators. They offer a versatile, specialty engineered material, annealed pyrolytic graphite (APG) for reliable performance.

Efficient heat dissipation to protect critical electronic components in space, under increasingly tight space requirements, is performed by k Technology’s k-Core passive thermal radiators, an example of the many Aavid Thermacore satellite thermal solutions.

Efficient heat dissipation to protect critical electronic components in space, under increasingly tight space requirements, is performed by k Technology’s k-Core passive thermal radiators, an example of the many Aavid Thermacore satellite thermal solutions.

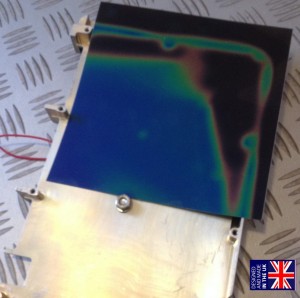

k Technology thermal radiators incorporate a proprietary concept featuring APG, a highly ordered crystalline material with a thermal conductivity of >1,500 W/m-K, within a high-strength structural shell material such as aluminium or carbon polymer composite. The thermal performance of each material is kept separate, with no shear force transferred across the encapsulant/APG interface.

Radiator Panel Benefits

- Reliable performance under a extreme temperatures (-40°C to +72°C)

- Thermal performance without the need for heat pipes (which require difficult semiconductor-heat spreader CTE matching)

- Rugged construction stands up to vibration launch loads and other stresses/pressures

- Reduced product cost, increased reproducibility

- Reduced size and weight, appropriate for the increasing density of electronic equipment and more limited space for thermal solutions

- Ability to dissipate high heat fluxes produced by next-generation spacecraft electronics

1 Octobre 2018 : Devis prix présentation techniques : contactez votre représentant en France – Suisse – Belgique ou directement à l’usine Anglaise :Adresse usine : Unit 12/Wansbeck Business Park/Rotary Parkway, Ashington NE63 8QW, Royaume-Uni / +44 1670 859500

Email France Belgique Suisse : Contact af-ingenierie.fr (formulaire antispam ci dessous)

http://management-thermique.fr/contactez-nous

http://management-thermique.fr/ Devis Contact Thermacore Europe

k Technology k-Core thermal spreaders effectively extract heat from a surface opposite to an area of concentrated heat load. The resulting thermal spreading effect dissipates heat quickly and significantly reduces both peak temperatures and temperature change (∆T) compared with traditional aluminium designs. The result is increased chip life and potentially higher-power operation.

k Technology k-Core thermal spreaders effectively extract heat from a surface opposite to an area of concentrated heat load. The resulting thermal spreading effect dissipates heat quickly and significantly reduces both peak temperatures and temperature change (∆T) compared with traditional aluminium designs. The result is increased chip life and potentially higher-power operation.

Among its primary thermal solutions, k Technology developed the patented k-Core heat transfer system, which uses encapsulated graphite to help alleviate heat in high-power electronics for applications in aerospace, military and commercial applications. The k-Core material uses APG as an insert within an encapsulating structure. k-Core can be fabricated by employing most conventional thermal management materials as the encapsulant (e.g., aluminium and copper alloys, ceramics, and composites), as dictated by user need and application. Light in weight, the passive k-Core system is highly conductive thermally and offers designers the ability to tailor coefficients of thermal expansion (CTE) if needed. The k-Core heat transfer system is typically designed for a specific application by our experienced engineering team.

Among its primary thermal solutions, k Technology developed the patented k-Core heat transfer system, which uses encapsulated graphite to help alleviate heat in high-power electronics for applications in aerospace, military and commercial applications. The k-Core material uses APG as an insert within an encapsulating structure. k-Core can be fabricated by employing most conventional thermal management materials as the encapsulant (e.g., aluminium and copper alloys, ceramics, and composites), as dictated by user need and application. Light in weight, the passive k-Core system is highly conductive thermally and offers designers the ability to tailor coefficients of thermal expansion (CTE) if needed. The k-Core heat transfer system is typically designed for a specific application by our experienced engineering team.